-

Energy and cost savings

·By optimizing energy recovery through the utilization of waste steam, it enhances energy efficiency and minimizes plant operating costs (OPEX).

·With no additional steam or cooling water required, the initial investment costs (CAPEX) can be reduced.

-

Sustainable and environmental-friendly technology

·Minimizing energy consumption leads lowest fossil fuel usage and CO2 emissions, and enables sustainable plant operations.

·ZLD (Zero Liquid Discharge) system enables environmental-friendly operations.

-

Fast installation and easy operation

·The simplified and optimized design of the evaporation process enables quick installation and easy operation.

-

Cost-effective and easy maintenance

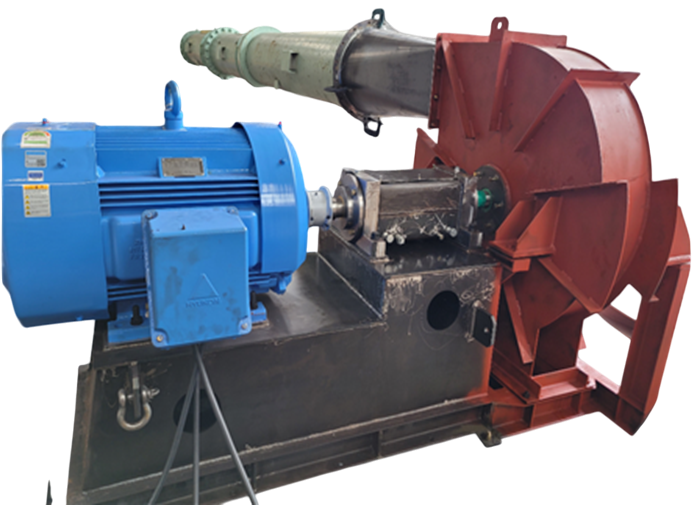

·The direct connection of the fan to the motor, along with the use of standard replacement parts, ensures cost-effective and straightforward maintenance.

-

24/7 Professional maintenance support

·We provide 24/7 professional maintenance support and ensure your equipment maintains optimal operating conditions in any environment.

Food & Beverage, Diary & Sugar

Production process of

- Milk, yogurt, and cheese

- Sugar and sweetener

- uice and sauce

Utility & Waste Water Treatment

ZLD (Zero Leakage Discharge) system

Water, wastewater, and sewage treatment

Desalination plant

Bio & Pharmaceutical

Enrichment process of

- Protein, glucose and etc.

- Lysin, vitamin and etc.

Chemical-Battery

Enrichment process of Sodium sulfate, Nickel, Lithium and etc.

Oil & Gas, Petrochemical & Chemical

Process of Distillation , Evaporation , Crystallization , Purification

| MODEL | MVR |

|---|---|

| Type | FAN |

| Flow | 600 ~ 3,000㎥/min |

| ∆T | 5 ~ 10℃ |

| RPM | 1,700 ~ 3,600 |

| Stage | 1 Stage (* Multi-stage processing is possible through serial connection ) |