-

High startup reliability

·Since the equipment employs a continuous combustion system using a dual injection nozzle equipped with a single-can combustor, there are almost no ignition failures during startup, as occur with diesel engines. Furthermore, there is no cooling water equipment, and thus fewer inspection items before startup. The system starts up quickly without fail and can be quickly connected to the load without warm-up operation.

-

Stable frequency characteristics

·The system is the single-shaft type which is the most suitable for an alternator drive source. There are few speed fluctuations, and it is possible to obtain a good frequency fluctuation rate during steady operation or when connecting/disconnecting the full load. This is impossible with a diesel engine or double-shaft gas turbine.

-

Excellent Instantaneous overload absorption

·The main shaft rotates at a high speed of 22,000~53,000rpm. This rotation speed is reduced to 1,500~1,800rpm, so the equivalent moment of inertia becomes extremely large, and the system can easily absorb the momentary overload when starting a high-capacity induction motor or similar equipment. The system has a much higher momentary overload capacity than diesel generation equipment in the same class. Gas turbines show their true value in the case of standby equipment, where it is particularly easy for momentary overloading to occur.

-

Simple maintenance

·Unlike diesel engines, gas turbines do not have reciprocating or sliding parts such as pistons and cylinders, and thus there is no friction between parts. Furthermore, since the number of parts is low, high startup reliability can be maintained with the little daily inspection. In addition, only once-a-month check operation is sufficient.

-

Cooling water is unnecessary

·The self-cooling system eliminates the need for cooling water, making maintenance unnecessary and preventing accidents caused by freezing or water shortages. For that reason, this equipment is more reliable than diesel engines requiring cooling water. It will also save the costs of cooling water equipment and pipe installation, and the system installation location can be freely chosen.

-

Noise can be easily removed

·The main component of the produced noise is in the easily blocked high-frequency range, so it can be curbed on the equipment side with a simple package, and exhaust noise can also be easily reduced using a silencer. Noise reduction can be achieved more easily than with diesel engines, whose main component is low frequency, and noise issues can be adequately handled even in cases where there are stringent restrictions on noise on the site boundary.

-

Extremely low vibration and outstanding earthquake-resistance

·As the system uses rotary motion engines with no reciprocating parts, there is almost no vibration. For this reason, no special foundation work or vibration isolation is needed during installation. In addition, there is almost no need for resilient mounting systems such as vibration isolation rubber or springs as vibration countermeasures, as in the case of diesel engines. As a result, the system has outstanding earthquake-resistance and causes little low-frequency vibration and resonance phenomena similar to seismic waves.

-

Clean exhaust gas

·Low-sulfur fuels such as kerosene and diesel oil can be used, and they are combusted completely. Therefore, the system achieves "clean exhaust" with extremely low levels of pollutants such as SOx (sulfur oxides) and NOx (nitrogen oxides) in discharged gas.

-

Space-saving and easy transport/installation

·Compared with diesel engines in the same class, gas turbines are surprisingly lightweight and small. With a compact package, they can be easily transported to and installed at cramped locations such as rooftops and basements. Furthermore, there is no need for cooling water equipment, so only a small installation area is necessary, and the space can be used effectively.

-

Compact Package

·The gas turbine engine and reducer are integrated and connected by a rubber/shear pin coupling, allowing both components to be installed on a single cradle. This results in a compact and efficiently designed package.

-

High-performance & High quality gas turbines

·The performance of gas turbines at the heart of these systems is world-class, and they are designed and fabricated rationally with the single-axis system optimal for an alternator drive source.

-

Quick and Thorough A/S support for maintenance

·Anytime, anywhere, quick and thorough maintenance support according to the customer's request is possible. In addition, supply the parts at an affordable price as well as an agency for consignment management is also available with superior maintenance support staff.So, it is possible to maintain the best operating condition with SA Engineering's perfect maintenance support

| ITEM / MODEL | PS200 | PS250 | PS250S | PS300 | PS375 | PS500 | PS500S | PS625 | PS750 | PS1000 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Generator set |

Rated Output (kW)40℃ | 150 | 180 | 200 | 240 | 300 | 350 | 400 | 500 | 600 | 800 | |

| Ambient Temp. | 5~40℃ | |||||||||||

| Altitude | Below 150m | |||||||||||

| Fuel Type | Kerosene, Diesel Oil | Kerosene, Diesel Oil, LNG | ||||||||||

| Start-up time | within 40-sec. | |||||||||||

| Load Application Capacity | 100% (Resistive load) | |||||||||||

| Freq. Deviation | 3±0.5% | |||||||||||

| transient | within ±4% (with 100% block load on and off) | within ±4.5% | ||||||||||

| Steady state | within ±0.3% | |||||||||||

| Fuel consumption (Diesel Oil ℓ/h) | 115 | 125 | 135 | 145 | 230 | 240 | 260 | 275 | 305 | 465 | ||

| Generator | Type | Type of protection (IP-21) | ||||||||||

| Rated Output (kVA)40℃ | 187.5 | 225 | 250 | 300 | 375 | 437.5 | 500 | 625 | 750 | 1,000 | ||

| Power Factor | 0.8 | |||||||||||

| Voltage (V) | 380/220 ~6,600 | |||||||||||

| Freq. (Hz) | 50/60 | |||||||||||

| Phase | 3 | |||||||||||

| Pole | 4 | |||||||||||

| RPM | 1,500/1,800 | |||||||||||

| Excitation System | AC exciter (Brushless mode) | |||||||||||

| Gas turbine |

Type | S1A-01 | S1A-02 | S1A-03 | S1A-06 | S1T-02A | S1T-02 | S1T-03 | S2A-01A | S2A-01 | M1A-01A | |

| Simple open cycle, single shaft | ||||||||||||

| Structure | compressor | Two stage, cnetrifugal type | ||||||||||

| Combustor | Cylindrical (Can Type) | |||||||||||

| Turbine | two stage axial | three stage axial | ||||||||||

| rated output 40℃ |

(kW) | 191 | 202 | 228 | 272 | 353 | 390 | 441 | 588 | 662 | 883 | |

| (PS) | 260 | 275 | 310 | 370 | 480 | 530 | 600 | 800 | 900 | 1,200 | ||

| RPM | 53,000 | 31,500 | 22,000 | |||||||||

| Lube Oil | Type | Synthetic oil/Shell ASTO-500, Mobil jet Ⅱ, Castrol AERO 5000, DP BPTO2380 | ||||||||||

| Capacity(ℓ) | 33 | 37 | 49 | 66 | 100 | |||||||

| Consumption(ℓ/h) | 0.025 | 0.05 | 0.08 | |||||||||

| Reducer | Parallel Gear | Planet Gear | ||||||||||

| Speed regulator | Electrical type | |||||||||||

| Starting System |

Electrical ※1 | a pair of MSE-24V-150AH | a pair of MSE-24V-300AH | a pair of MSE-48V-300AH | a pair of MSE-60V-500AH | |||||||

| pneumatic (Air Tank & Compressor) |

- | 1.5㎥ 2units / 3.7kW 1Unit |

2.5㎥ 2 units / 5.5kW 1unit |

|||||||||

| Control Power | a pair of ES-24V-130AH | a pair of ES-24V-130AH (separate DC voltage converter) | ||||||||||

| ITEM / MODEL | PS1250 | PS1500 | PS1750 | PS2000 | PS2500 | PS3000 | PS3500 | PS4000 | PS4500 | PS5000 | PS6000 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Generator set |

Rated Output (kW)40℃ | 1,000 | 1,200 | 1,400 | 1,600 | 2,000 | 2,400 | 2,800 | 3,200 | 3,600 | 4,000 | 4,800 | |

| Ambient Temp. | 5~40℃ | ||||||||||||

| Altitude | Below 150m | ||||||||||||

| Fuel Type | Kerosene, Diesel Oil, LNG | ||||||||||||

| Start-up time | within 40-sec. | ||||||||||||

| Load Application Capacity | 100% (Resistive load) | ||||||||||||

| Freq. Deviation | 3±0.5% | ||||||||||||

| transient | within ±4.5% | within ±5% | |||||||||||

| Steady state | within ±0.3% | ||||||||||||

| Fuel consumption (Diesel Oil ℓ/h) | 525 | 620 | 695 | 695 | 1,065 | 1,245 | 1,385 | 1,390 | 1,525 | 1,835 | 2,050 | ||

| Generator | Type | Type of protection (IP-20) | |||||||||||

| Rated Output (kVA)40℃ | 1,250 | 1,500 | 1,750 | 2,000 | 2,500 | 3,000 | 3,500 | 4,000 | 4,500 | 5,000 | 6,000 | ||

| Power Factor | 0.8 | ||||||||||||

| Voltage (V) | 380/220 ~6,600 | 3,300/6,600 | |||||||||||

| Freq. (Hz) | 50/60 | ||||||||||||

| Phase | 3 | ||||||||||||

| Pole | 4 | ||||||||||||

| RPM | 1,500/1,800 | ||||||||||||

| Excitation System | AC exciter (Brushless mode) | ||||||||||||

| Gas turbine |

Type | M1A-01 | M1A-03 | M1A-06 | M1A-23 | M1T-01S | M1T-03 | M1T-06 | M1T-23 | M1T-23S | M1T-33A | M1T-33 | |

| Simple open cycle, single shaft | |||||||||||||

| Structure | Compressor | Two stage, cnetrifugal type | |||||||||||

| Combustor | cylindrical (Can Type) | ||||||||||||

| Turbine | Three stage axial | Four stage axial | |||||||||||

| rated output 40℃ |

(kW) | 1,118 | 1,368 | 1,567 | 1,765 | 2,317 | 2,663 | 3,089 | 3,457 | 4,362 | 4,362 | 5,200 | |

| (PS) | 1,520 | 1,860 | 2,130 | 2,400 | 3,150 | 3,620 | 4,200 | 4,700 | 5,300 | 5,930 | 7,070 | ||

| RPM | 22,000 | 18,000 | |||||||||||

| Lube Oil | Type | Synthetic oil/Shell ASTO-500, Mobil jet Ⅱ, Castrol AERO 5000, DP BPTO2380 | |||||||||||

| Capacity(ℓ) | 100 | 165 | 160 | 240 | 370 | ||||||||

| Consumption(ℓ/h) | 0.08 | 0.16 | 0.2 | ||||||||||

| Reducer | Planet Gear | Parallel Gear | Planet Gear + Parallel Gear | ||||||||||

| Speed regulator | Electrical type | ||||||||||||

| Starting System |

Electrical ※1 | a pair of MSE-60V-500AH | Two pair of MSE-60V-500AH | Two pair of MSE-60V-600AH | Four pair of MSE-60V-500AH | ||||||||

| Pneumatic (Air Tank & Compressor) |

2.5㎥ 2 units / 5.5kW 1unit | 3㎥ 2units / 5.5kW 1unit | 5㎥ 2units / 5.5kW 2units | 6㎥ 2units / 5.5kW 2units | 6㎥ 2units / 5.5kW 3units | 7㎥ 2units / 5.5kW 3units | 6㎥ 6units / 5.5kW 6units | ||||||

| Control Power | a pair of HS-24V-30AH (separate DC voltage converter) | ||||||||||||

· Standard fuel consumption is the standard value at an ambient temp of 15℃, Altitude of 150m, and rated output occurs with diesel.

* error range: 5% (under PS500S is 6%)

· The capacity of starting system enables continuous fifth-times starting.

※ Please consult us If the GD2 of the generator is large, and battery capacity and quantity are changed.

※ Above PS625 model can use gas fuel. Therefore, it needs consultations with us.

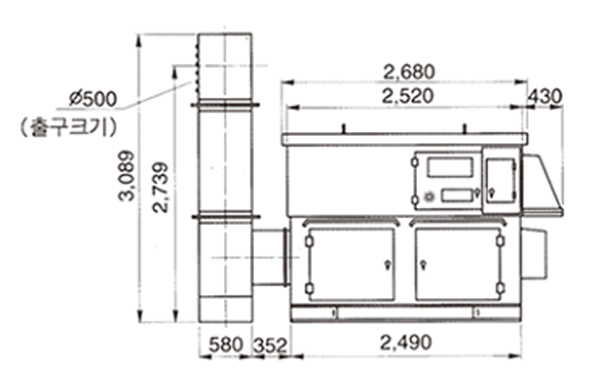

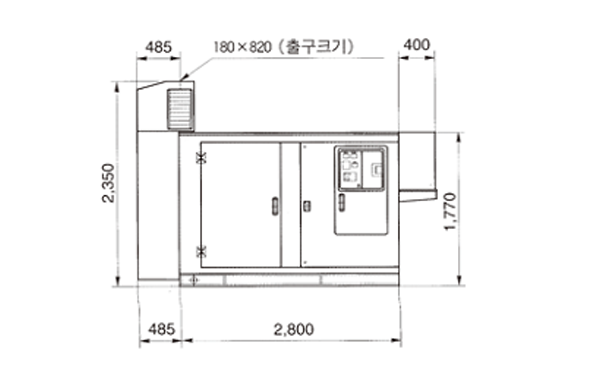

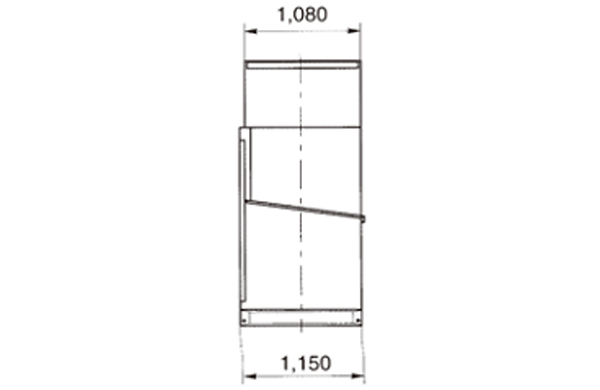

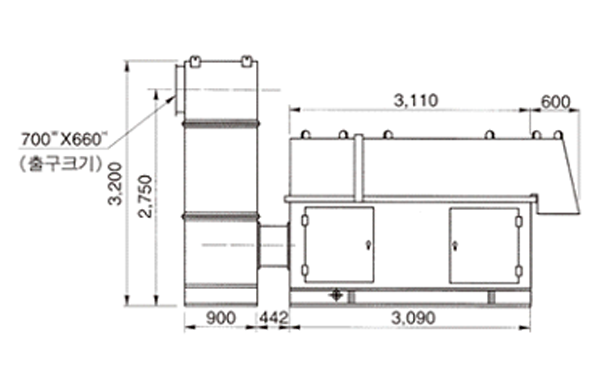

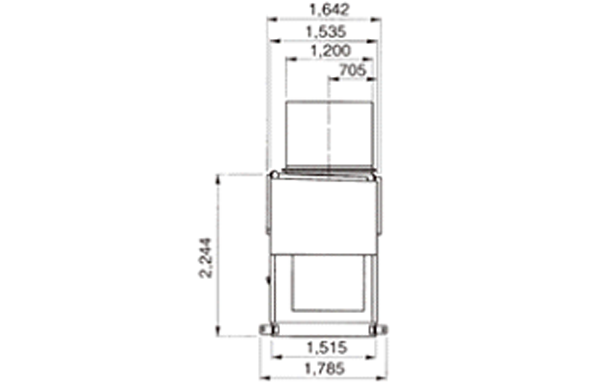

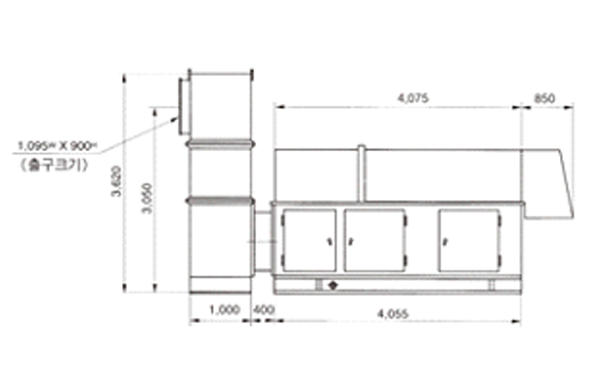

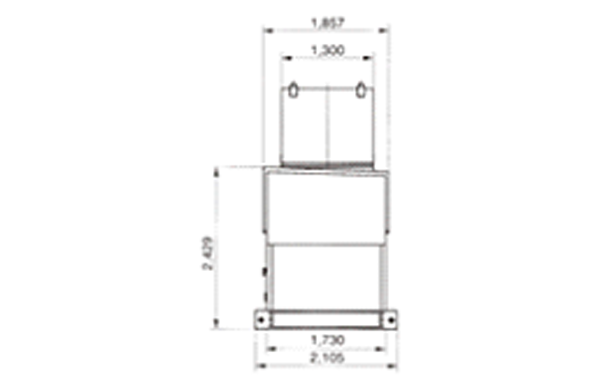

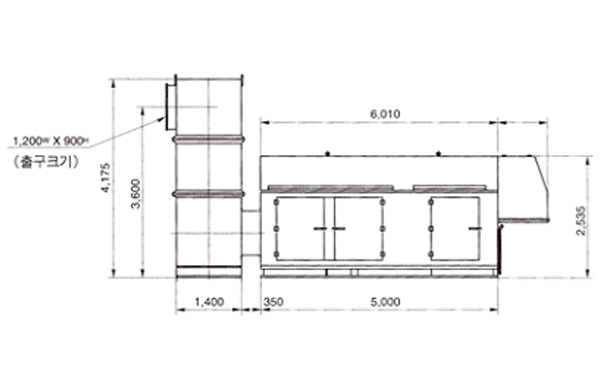

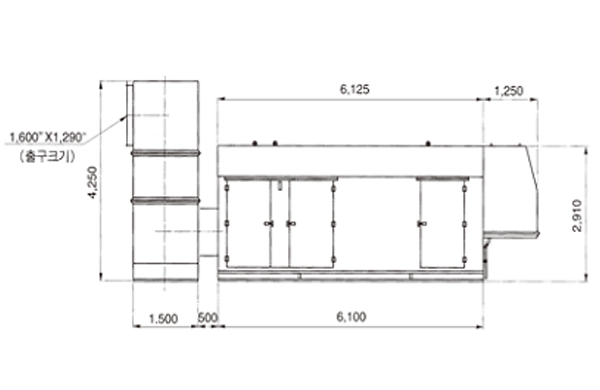

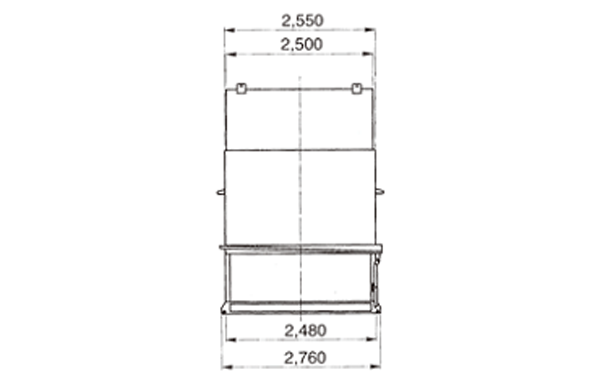

PS200 / 250 / 250Stype(for low voltage)

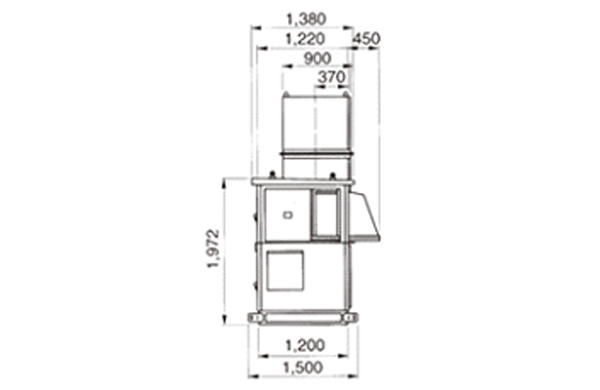

PS300 (for low voltage)

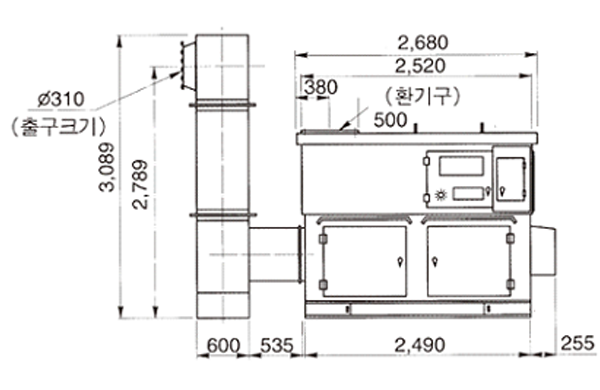

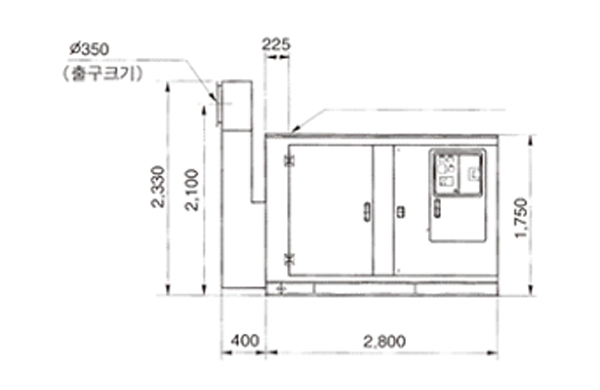

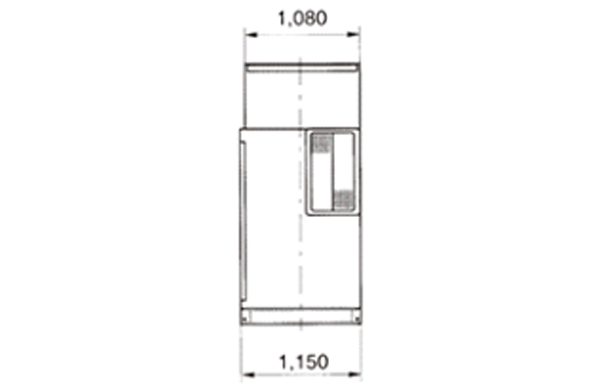

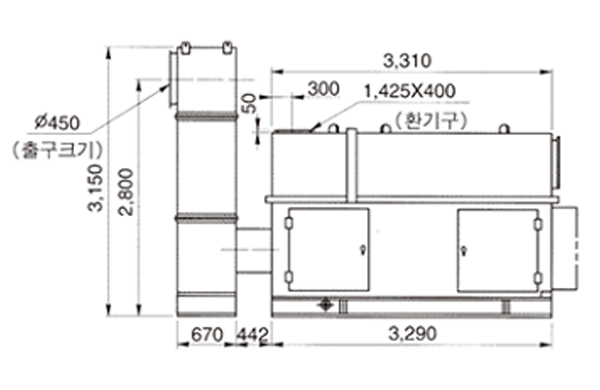

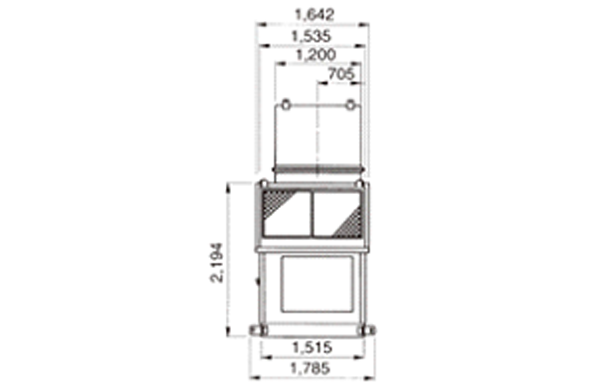

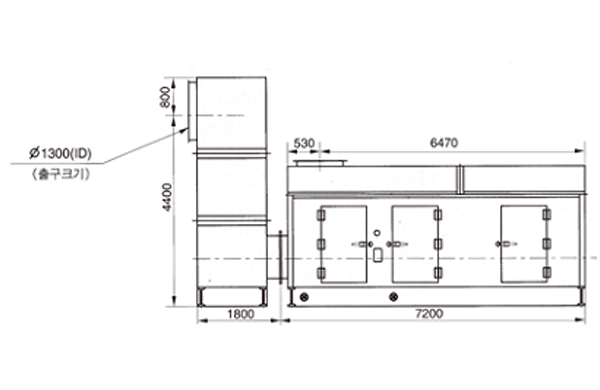

PS375 / 500 / 500Stype

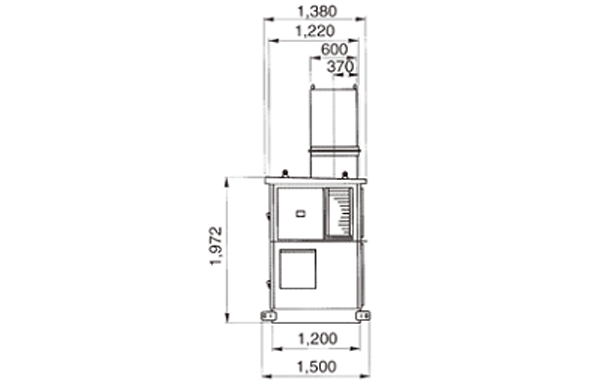

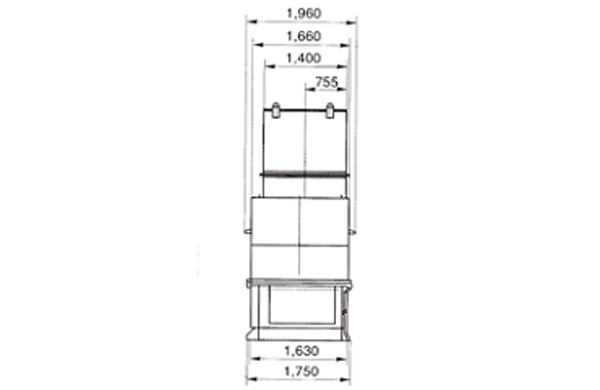

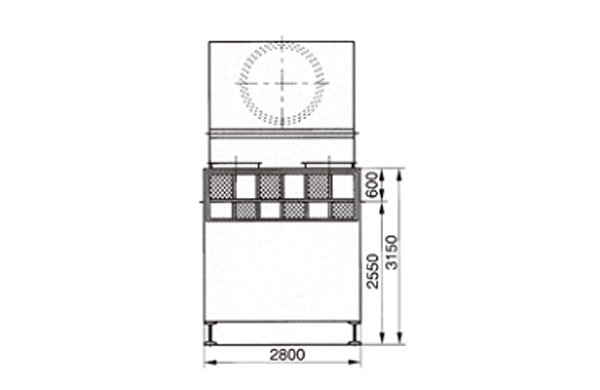

PS625 / 750type

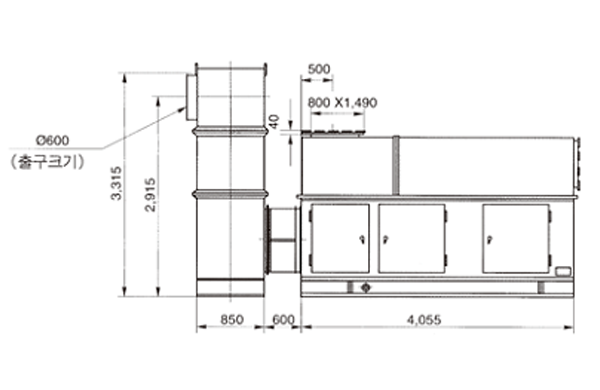

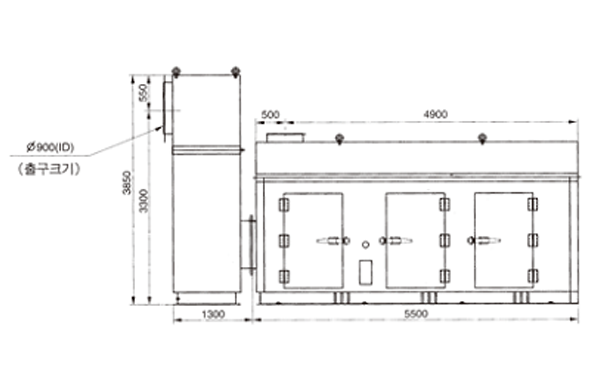

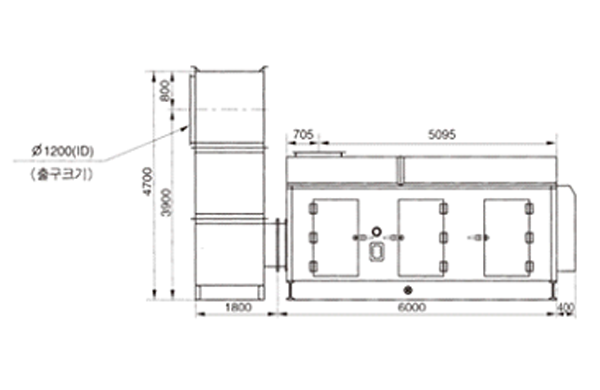

PS1000 / 1250 / 1250 / 1750type

PS2000 / 2500type

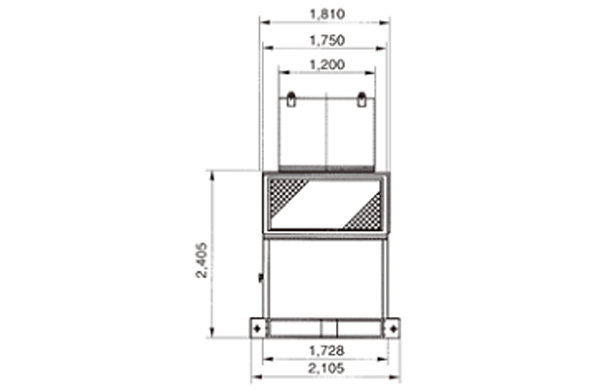

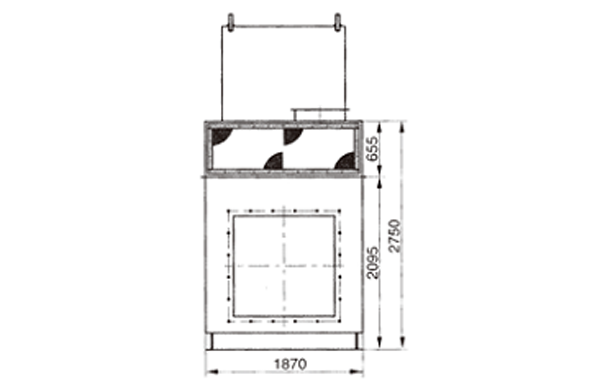

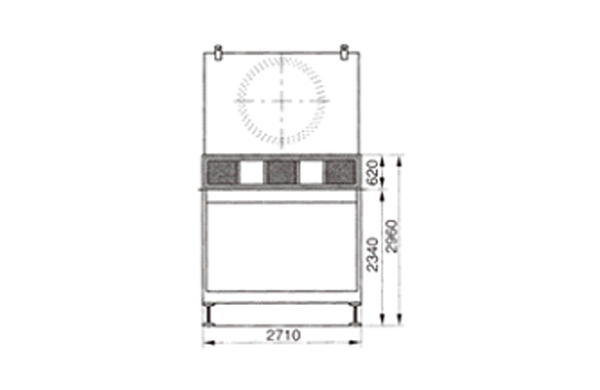

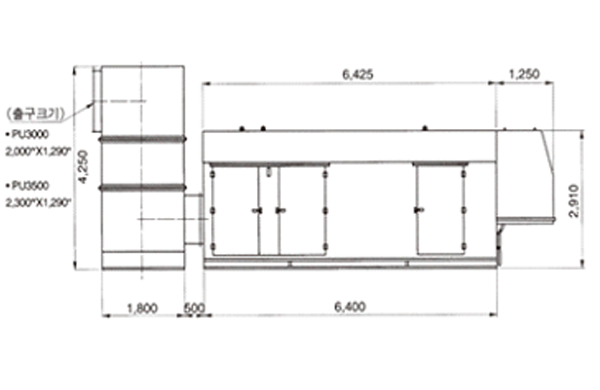

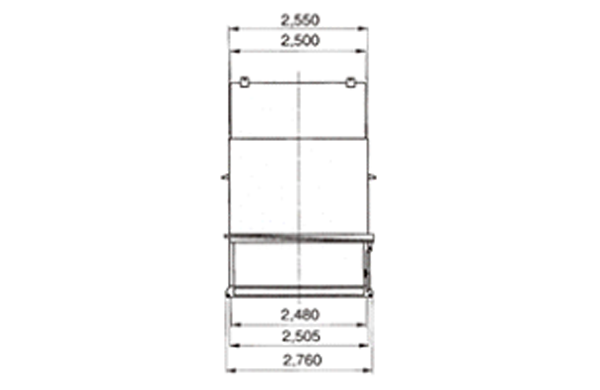

PS3000 / 3500type

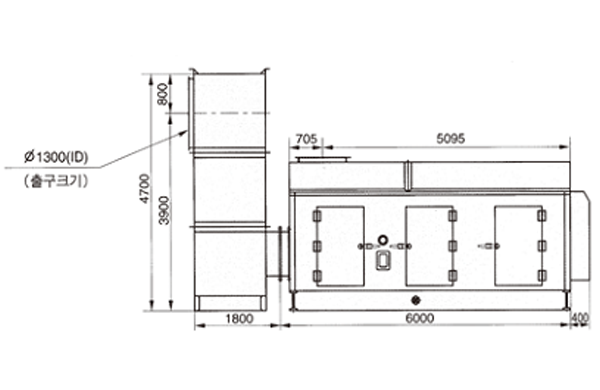

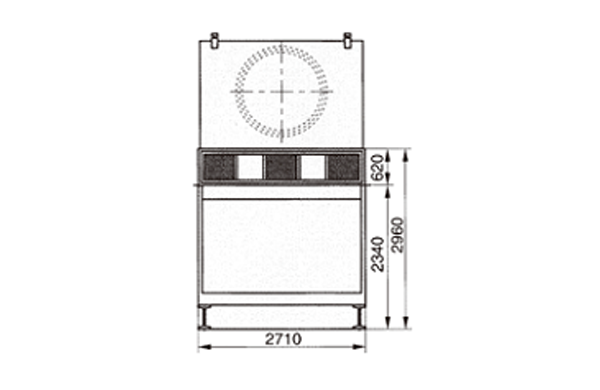

PS4000 / 4500type