-

The most cost effective technology for driving down your energy

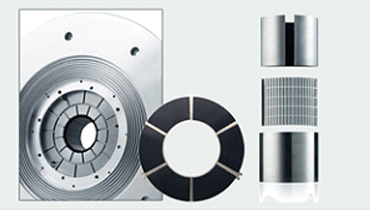

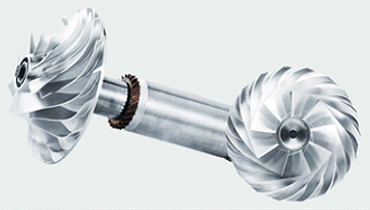

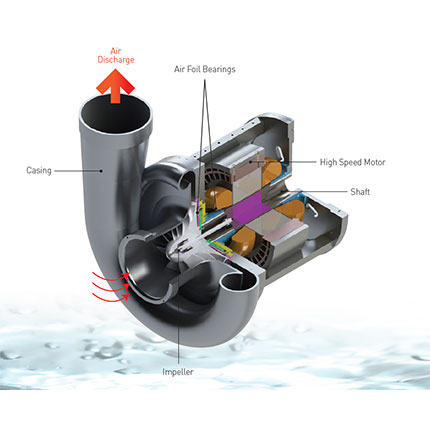

·We provide stable and reliable products through the optimal balancing of core technologies such as air foil bearings, high-speed motors, and high-efficiency impellers.

·Our optimal Variable-frequency drive (VFD) technologies minimize energy consumption and maximize efficiency

-

Providing all-in-one packages of what you want

·We provide competitive package products that integrate all functions, including blower, PLC, and inverter.

·No need for extra supplementary installation—saves space, time, and cost for installation.

-

Keeping working environment with your peace of mind

·No worries about lower productivity and cost increase from oil contamination as we provide 100% oil-less compressed air

·Provides a pleasant working environment—low noise, less than 80dB(A), and low vibration without additional foundation work.

-

An economic perspective

·Short payback period of early investment costs (2~3 years)

·Reduction of electricity cost (30~40% higher compared to existing blower)

·Possibility of minimizing effort and cost for installation or maintenance (Periodic exchange of filter necessary)

·No necessity of groundwork for installation

·Possibility of efficient utilization of installation space with a small area of installation

-

Technique application perspective

·Applying to high-efficiency turbo equipment technology Compressor, compression and expansion machine, freezer, generator, etc.

·Possibility of applying automobile fuel battery and distributed power air supply system

·Possibility of being linked to the automobile control system

-

Environmental perspective

·No vibration with less noise

·Providing a pleasant working environment for workers

·Advantageous for interior installation

·Easy to instal in high-density residential zone: less concern for occurrence of a civil complaint

·No environmental pollution caused by waste lubricating oil

·production of clean compressed air: not mixed with oil

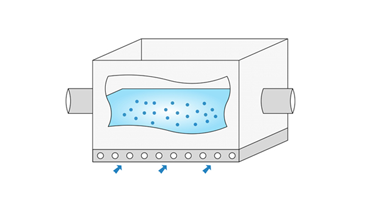

Wastewater Treatment

Supply of clean compressed air for wastewater disposal from sewage wastewater treatment plants, purification plants, agricultural stockbreeding excreta treatment plants

The supply of compressed air at a lower temperature than that of existing blowers increases the efficiency of water treatment.

Possibility to install in high-density residential zones thanks to less noise.

Application on sump, aeration tank(reactor), high-level processing, filter bed, etc

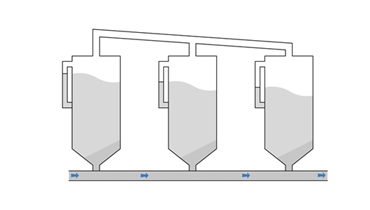

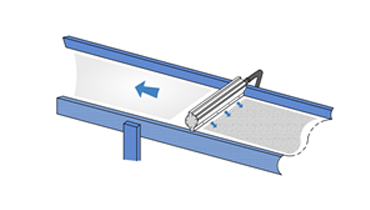

Transfer of cement, petrochemical raw materials.

Transfer of raw material for cement, petro chemistry fuel (Pellet, etc.), and various raw materials in the form of pulverulent body through compressed air

Maximized transfer efficiency compared to the belt type conveyor type conveyer, realization of installation space

Exhibition of strong durability against poor usage environment such as dust or foreign substances by using high-speed induction motor

Minimization of maintenance cost through modulation of main parts such as air bearings

Other

Application in general industrial sites such as dry line, dehumidification, burner, etc.

Drying the product without a separate heating device, use of compressed air compressed by high temperature

Increased production efficiency through shortening of the recycle time for dehumidification process

| MODEL | GT5 | GT10 | NGT20 | NGT30 | NGT50 | NGT75 | NGT100 | |

|---|---|---|---|---|---|---|---|---|

| Suction Flow(㎥/min) | 3.5~4.6 | 6.5~8.0 | 12.0~19.0 | 18.0~26.0 | 16.0~44.0 | 22.0~62.0 | 28.0~71.0 | |

| Dis.Pressure(kgf/㎠G) | 0.3~0.6 | 0.3~0.8 | 0.3~1.5 | |||||

| Dimension | W (㎜) | 600 | 750 | 750 | 850 | |||

| D (㎜) | 850 | 1530 | 1600 | 2000 | ||||

| H (㎜) | 900 | 1150 | 1150 | 1370 | ||||

| MODEL | NGT125 | NGT150 | NGT200 | NGT250 | NGT300 | NGT350 | NGT400 | NGT500 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Suction Flow(㎥/min) | 46.0~98.0 | 63.0~120.0 | 86.0~162.0 | 90.0~193.0 | 130.0~255.0 | 144.0~266.0 | 172.0~324.0 | 186.0~376.0 | ||

| Dis.Pressure(kgf/㎠G) | 0.3~1.0 | |||||||||

| Dimension | W (㎜) | 950 | 950 | 950 | 1300 | 1600 | 1600 | |||

| D (㎜) | 2250 | 1950 | 2050 | 2000 | 2100 | 2310 | ||||

| H (㎜) | 1500 | 1500 | 1550 | 1765 | 1810 | 1810 | ||||