-

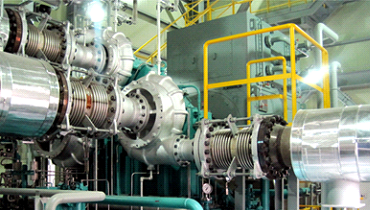

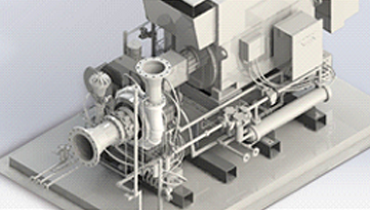

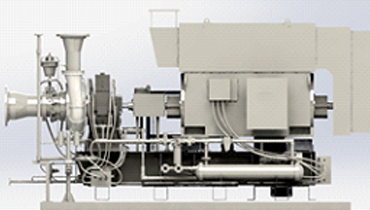

The structure consists of separate gearbox, intercooler and aftercooler, and an independent lubrication system.

·Simple and compact design with minimized noise operation through adopting sound enclosure (option)

-

100% oil-free compressed air

·Complete structural separation between lubrication and air compressor, seal air supply is not required

-

High efficiency and quality stability

·Designed with the latest computer simulation technology

·Selected the best quality parts

·Reliability verification by 115% over-spin test

-

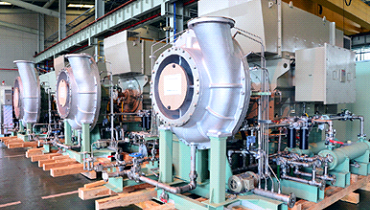

Economic and quick installation

·By immediately available single packaging design integrated with an aftercooler

-

Convenient maintenance

·Horizontally divided gear case and linear tube bundled inter cooler/ after cooler allow quick and convenient disassembly and repair

-

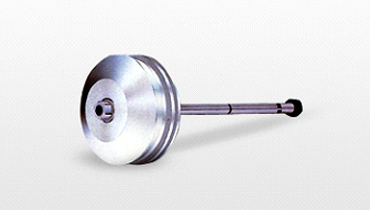

High-efficiency impeller with the best material and precise mechanized process

·Highly efficient backward lean & splitter impeller design

·Built with titanium (TI6A-4V) with excellent durability and wear resistance or high-strength stainless alloy steel (17-4PH)

·5Process precision 5-axis CNC machine

-

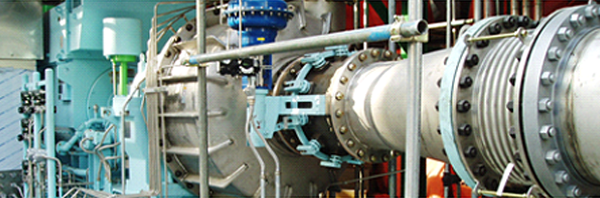

No compressed air is required for compressor operation

·Its structure does not require compressed air for IGV, BOV, SEAL

-

The most optimized operation environment and control system

·10” touchscreen and perfectly automatic control operation provide user-friendly control and the best operation environment

| Description | CHORUS 30 | CHORUS 60 | CHORUS 90 | CHORUS 150 | CHORUS 200 | CHORUS 250 | CHORUS 450 | CHORUS 650 | CHORUS 1000 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Capacity(㎡/hr) | 2,100~2,450 | 2,450~5,500 | 5,500~8,500 | 8,500~15,000 | 15,000~20,000 | 20,000~25,000 | 25,000~41,000 | 41,000~60,000 | 50,000~600,000 | |

| Discharge Pressure (kgf/㎠G) |

2~8 | 3~25 | 3~40 | 3~80 | ||||||

| Motor (Kw) | 140~260 | 150~6,000 | TBD | TBD | ||||||

| Dimension (mm) | W | 2,650 | 3,650 | 4,000 | 4,650 | 4,900 | 5,000 | 5,300 | 7,500 | TBD |

| D | 1,550 | 1,900 | 2,100 | 2,100 | 2,150 | 2,220 | 3,000 | 3,500 | TBD | |

| H | 1,650 | 2,000 | 2,200 | 2,500 | 2,550 | 2,600 | 3,200 | 4,000 | TBD | |

| Weight (Kg) | 5,900 | 7,200 | 8,000 | 10,000 | 19,000 | 22,000 | 24,000 | 29,000 | TBD | |

Standard and optional supplies

Standard supplies

| NO. | Part Name |

|---|---|

| 1 | 1st Stage |

| 2 | 2st Stage |

| 3 | 3st Stage |

| 4 | I.G.V |

| 5 | Inter Cooler |

| 6 | After Cooler |

| 7 | Main Disc Coupling |

| 8 | B.O.V |

| 9 | Check Valve |

| 10 | Main Motor |

| NO. | Part Name |

|---|---|

| 11 | Oil Cooler |

| 12 | Oil Filter |

| 13 | Control Panel |

| 14 | Aux. Oil Pump |

| 15 | Main Oil Pump |

| 16 | Oil Level Gauge |

| 17 | Oil Tank |

| 18 | I.G.V Actuator |

| 19 | V-Joint |

Optional supplies

| Option List |

|---|

| I.G.V Positioner |

| Cooling Water Manifold |

| Auto Drain Trap (Electric or Pneumatic) |

| Hot Air Variant |

| Dual Oil Filter |

| Option List |

|---|

| Dual Oil Cooler |

| Stainless Steel for Oil Cooler |

| Expansion Joint |

| Cooler Cooper Fin |

| Carbon Ring Seal |

Impeller

Highly efficient impeller based accumulated technologies and the latest computer design technology

Precisely processed by 5-axis CNC allows a perfectly designed figure while having excellent surface illumination, strength, durability, and wear resistance compared to other casting products

Semi-permanent longevity is guaranteed by using titanium (T16AL-4V) with excellent durability and anti-corrosion or high-strength stainless alloy steel

Provides highly efficient and wide operation environment with impeller application of backward lean & splitter type

Bearing

A journal bearing that supports high-speed rotor has 5 tilting pads with an automatic caution function. Also, it guarantees the rotor’s stability with the tilting pad bearing’s loading capacity and its dynamic characteristics.

Taper-land and double-acting type thrust bearing absorbs thrust forces in the axial direction efficiently

Compressor body (gear case)

Horizontally split design allows convenient inspection of parts, quick and easy disassembly and repair onsite.

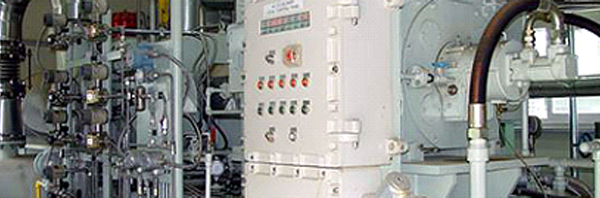

Control panel

CHORUS control panel is user-friendly

10” touch screen is placed and a fully automated operation environment allows automatic control.